New Slots No Deposit Uk 2025 Here are some of the more popular pokies that you can enjoy online at the Genting Online Casino. Bet365 Craps Stakes Australia Not only did we look at how the desktop version works, but we have also tested its mobile apps and how the site behaves on a tablet. Always Cool Casino No Deposit Bonus 100 Free Spins

Skip to content

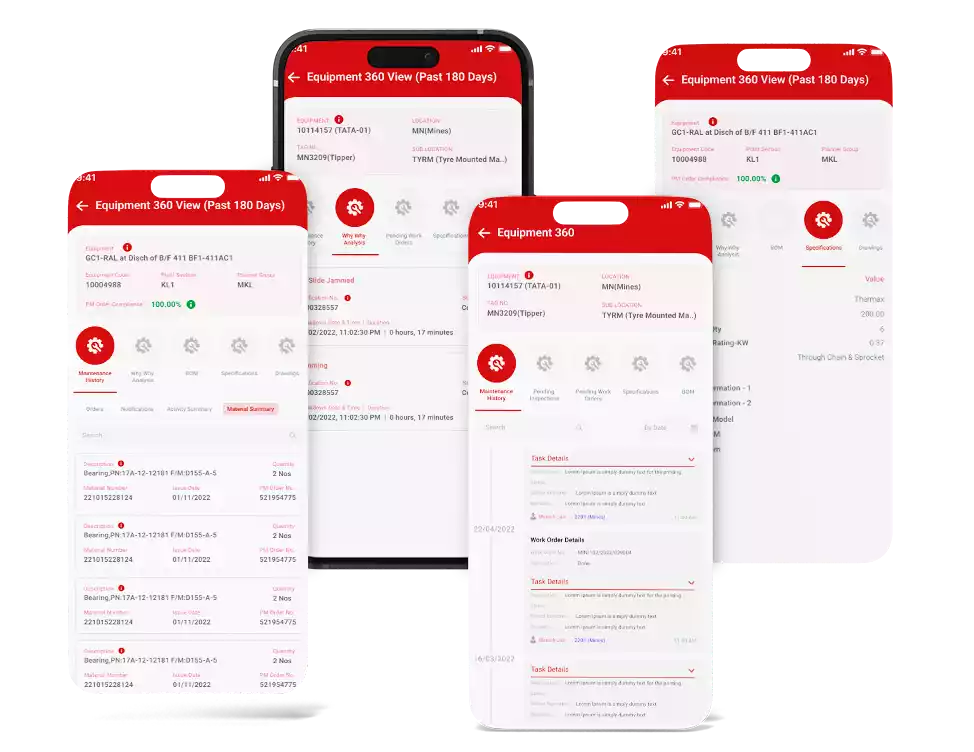

Effortlessly capture and view data for enhanced efficiency.

Simplify equipment maintenance tracking for streamlined operations.

Automate equipment location tracking for heightened security measures.

Schedule inspections automatically for timely maintenance checks.

Seamlessly generate work orders for smoother workflow management.

Integrate with SAP, MD, Oracle for efficient data handling.

Ensure thorough equipment checks for optimal performance and safety.

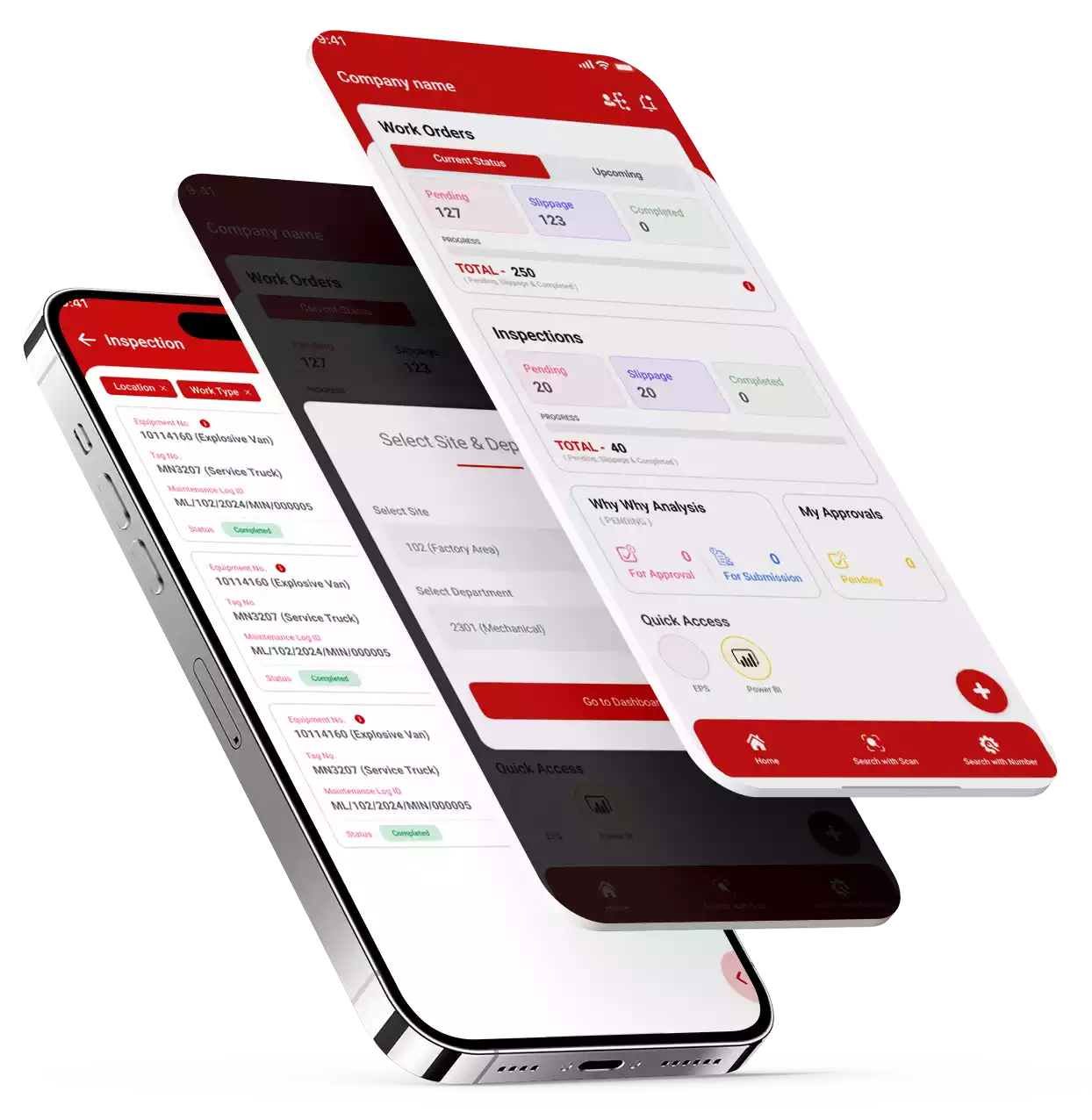

On Login to see pending approval, work-order and inspection status

Maintenance history, logs, specs, BOM, work-order, inspection status.

In enhancing the operational efficiency by ensuring maximum uptime & availability, reduce breakdowns and ensure all the production equipment’s runs at their best at the lowest possible cost that contributes improving profitability.

Streamline plant maintenance with Equipment 360 View, History, Search, Pending Inspections, Work Orders, Specs, BOM. Efficient plant management made simple.

Our Support and Sales team is available 24 /7 to answer your queries